DTF transfers are one of the latest printing methods to enter the market and their popularity is growing significantly. As a popular technique to print on all types of apparel and materials, they are quickly overtaking the likes of DTG and sublimation as the top printing method.

In this blog, we’ll be breaking down everything you need to know about DTF transfers, to help you on your journey to better quality prints.

- What does DTF transfer mean?

- The benefits of DTF transfers

- The drawbacks of DTF transfers

- What equipment do I need to make DTF transfers?

- Conclusion

- FAQs

What Does DTF Transfer Mean?

DTF stands for direct to film. DTF transfers are full color transfers that can be applied to a variety of garments, materials and substrates - whether they’re light or dark colored.

With this technique, you are able to print your design directly onto film, which is then transferred onto your garment of choice.This helps to improve the speed of the transfer as well as improving the ease of application.

What Are The Benefits Of DTF Transfers?

DTF is a revolutionary printing technique. The benefits of this method include:

- Versatility on materials

- Color capabilities

- Cost effective to do at home

- Ease of application

- No need to pre-treat

- Durability

Versatility On Materials

The biggest benefit of DTF transfers is their ability to be applied to any material. Even the most particular materials can be used with this printing method. Some of the materials you can use include 100% cotton, 50/50 blends, polyester, nylon, leather, silks and more.

Color Capabilities

Print on light or dark garments or even consider neon colors for your next design. DTF’s capabilities open up endless possibilities. They can effortlessly handle white as well as CMYK colors. The white ink will form the foundation of the print, and any colored pigments will be printed on top to help improve vibrancy.

Cost Effective To Do At Home

If you have a side hustle or are using DTF for your business, a benefit for you is that they are cost-effective to do at home. For example, if you’re selling custom shirts, you don’t have to press until you sell, rather than having to store pre-printed inventory. DTF supplies are also significantly more affordable than other printing methods if you want to create the transfers yourself.

Ease of Application

Applying the transfers to garments is simple - you can use either a heat press machine, crafting press or even a household iron. Just remember to press twice! Follow our DTF press instructions for more details.

No Need To Pre-Treat Garments

If you’re used to the world of DTG printing, you may remember the process of pre-treating your garments before applying transfers. In DTF, this step isn’t necessary, meaning your production timeline can be sped up drastically.

Durable & Washable

Unlike DTG which lasts approximately 6-10 washes before fading, DTF will remain bright even after 60+ washes! This is similar to screen printing.

What Are The Drawbacks Of DTF Transfers?

Some of the drawbacks of DTF transfers include:

- Gradients

- Specialist printers

Gradients

Gradients are more difficult to produce with DTF than some other printing methods like sublimation. However, at DTFTransfers, we offer an art automation which can create a gradient effect with predictable halftone dots. Speak to our experts to find out more!

Specialist Printers

If you are printing DTF transfers yourself at home, then you will require a specialized printer. It will require a desktop inkjet printer and specialist textile inks designed for this type of printing.

What Equipment Do I Need To Create DTF Prints?

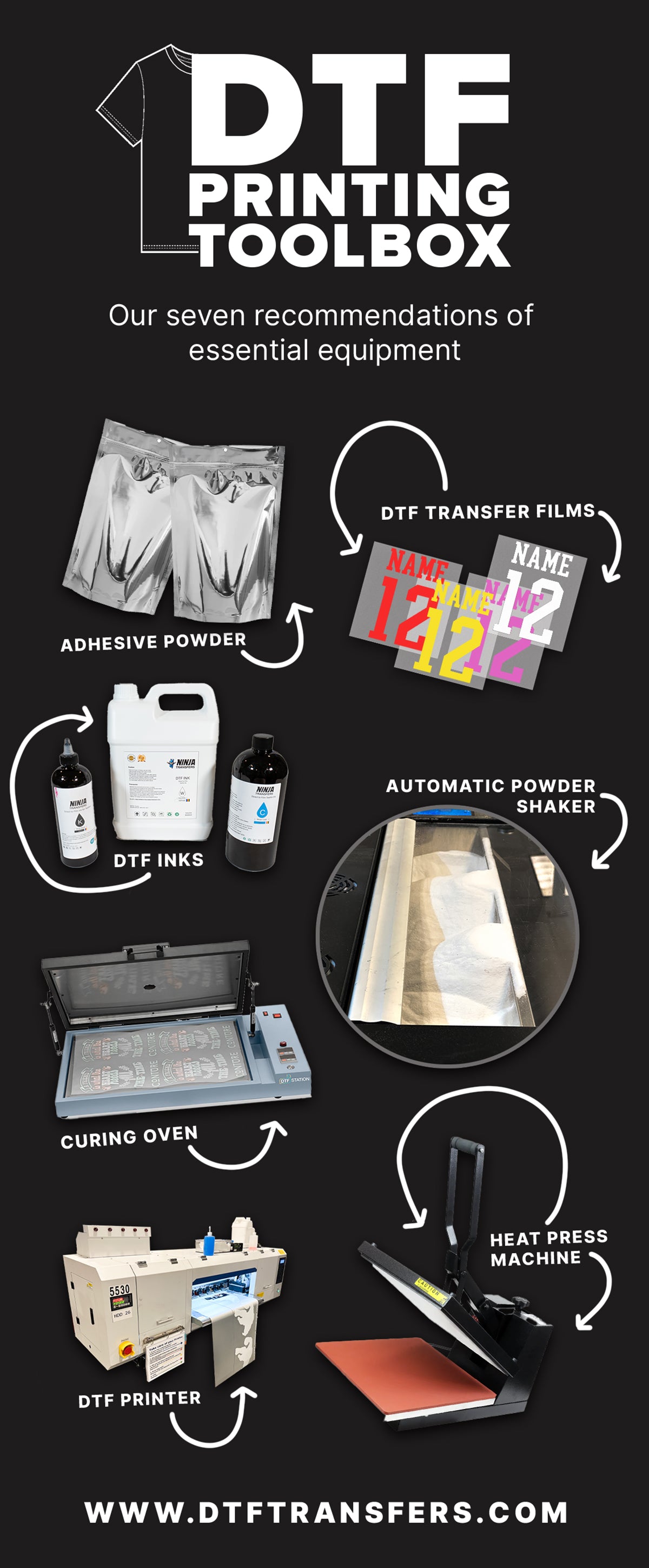

To produce stand-out DTF prints, you will need the following equipment:

DTF Printer

A specialist DTF printer will be needed to produce the best quality designs.

DTF Transfer Films

PET films are used to print your design. Choose between cold-peel and hot-peel.

Adhesive Powder

Adhesive powder helps to bind the color pigments to the transfer.

DTF Inks

CMYK, white and black DTF inks can be used to create your design. The white ink will form the base of the design.

Automatic Powder Shaker

Suitable for commercial use, this helps to remove excess powder and applies the powder evenly to the transfer.

Curing Oven

This melts the powder to create the transfer film. Alternatively, use a heat press ideally in no-contact mode.

Heat Press Machine

This will transfer the printed images to the desired surface or fabric. Hand-held heat presses and irons can also be used, however a heat press machine is recommended.

Alternatively, use DTF Transfers to produce DTF designs for you, so all you need to do is apply them to your apparel!

Conclusion

While this article answers the question ‘what is a DTF transfer’, there are many intricacies to the process that can help you to produce the best results. Stand out from the crowd with this revolutionary technology and get ahead of your competition. Turn to DTFTransfers.com for help creating your custom DTF transfers, today.

FAQs

Are DTF and screen printing the same?

No, these are entirely different techniques which use different equipment and supplies in order to produce the design. The quality of the two techniques is also arguably different, with DTF being the preferred method for vibrant and long-lasting prints. Learn more about DTF vs. screen printing.

Can you print DTF on a standard printer?

It is important to use only specialist equipment when printing DTF transfers to ensure the quality and longevity is kept. If you’re not able to print at home, our DTF gang sheets and DTF transfers by size can be an affordable solution.

Can you use DTF on any shirt?

Yes! DTF is completely versatile and can be used with any type of shirt or material. Other methods, like DTG, require 100% cotton only.

Can DTF printed apparel go in the washer and dryer?

Yes, they can be washed 60+ times without fading and can be placed in the dryer, similar to screen printed apparel. If you’re experiencing some wrinkling after washing, then use an iron on a low heat to take these out. Top tip: to improve longevity, wash your apparel inside out!