Whether you’re a business, side hustle, or a hobbyist, being able to apply transfers to your garments in the most efficient way that will ensure that they last is important. Properly applying your transfers will make sure you produce quality products at all times.

So, if you have your DTF transfers ready to go but you’re not sure what temperature you should be storing, pressing and washing your transfers and garments at - we have you covered! No matter the type of garments you are pressing on or the designs that you are transferring, our guide below can help to make sure you get the right results, every time.

Read on to find out more!

Table Of Contents

- DTF Film Type

- Material Type

- Using A Heat Press

- Using A Hand Held Press

- Using An Iron

- Transfer Time

- Peel Time

DTF Film Type

There are different types of films on the market which may require different temperature and time requirements to ensure the perfect finish. Check the manufacturer's instructions and recommended settings to ensure the film type is applied correctly at the appropriate temperature.

Material Type

The material that you are transferring designs onto will play a significant role in the quality of your final product but also on the heat and length of time you should press for. This is because different materials will require different temperature settings to achieve optimal adhesion and vibrancy. One of the biggest benefits of DTF transfers is that they can be applied to any type of material and garment unlike other methods like DTG and sublimation. Some of the most popular material types include cotton, polyester and blends.

Below we have broken down the three most common material types and the average temperatures that you should use to press them below:

|

Material |

Temperature (Fahrenheit) |

|

100% Cotton |

350-375°F |

|

Polyester |

300-325°F |

|

Cotton-Poly |

325-350°F |

Using A Heat Press

When using a heat press to press your transfers, temperatures can range from 300°F-320°F / 160°C. The exact temperature will depend on the DTF film and material - cotton will require more heat than other materials like polyester and blends. You should also use medium pressure to apply the transfer for approximately 12-15 seconds.

Using A Handheld Press

When using a handheld press, you should make sure to monitor the temperature carefully. Start at a lower temperature and then adjust as needed. Again, this temperature will vary depending on the specific handheld press, but we recommend setting your press at 320°F. Press your transfer for approximately 20 seconds. If that temperature is not hot enough, then increase it by 15 degrees and try again. Continue to scale until your transfer is adhered to the garment properly. It’s not possible to overpress a transfer, so you can play with the settings until you find the perfect choice. This will need to be pressed using hard pressure.

When using a handheld press, you should make sure to monitor the temperature carefully. Start at a lower temperature and then adjust as needed. Again, this temperature will vary depending on the specific handheld press, but we recommend setting your press at 320°F. Press your transfer for approximately 20 seconds. If that temperature is not hot enough, then increase it by 15 degrees and try again. Continue to scale until your transfer is adhered to the garment properly. It’s not possible to overpress a transfer, so you can play with the settings until you find the perfect choice. This will need to be pressed using hard pressure.

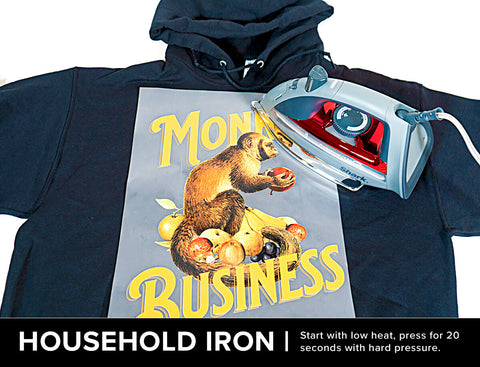

Using An Iron

When using an iron for DTF transfers, getting even heat distribution is important. Irons are less precise than heat presses which is why we recommend using a heat press for transfers instead. However you can still get fantastic results using a household iron!

Pay close attention to the temperature settings on an iron to ensure your transfers are properly protected and even consider using a thermometer to verify the iron’s actual temperature. Start on a lower setting first of all to prevent any scorching or melting of the material. Correspond the iron with the material that you are dressing on. If that is not hot enough, increase it towards the cotton/linen setting.

Remember to use parchment paper or a guard sheet over the transfer and press for 20 seconds with hard pressure.

Transfer Time

The transfer time is dependent on the equipment and material that you’re using. It may range from 20 seconds to 60 seconds or even more!

Conduct tests on scrap pieces of fabric and materials to find the right transfer time and follow manufacturer’s guidelines for your specific setup.

Peel Time

After you have transferred to your garment, you may find that some types of film require different time periods before peeling.

With our DTF transfers, you should ensure that they are cool to the touch before you attempt to peel the transfer.

Conclusion

No matter whether you’re choosing to press your DTF transfers with a heat press, a handheld press or a household iron, knowing the right temperatures to choose can help to ensure your custom garments stay vibrant and durable.

Remember, there is no ‘over-pressing’ a DTF transfer, but you should be careful particularly with a household iron to avoid scorch marks or burning your fabrics. One of the biggest benefits to a DTF transfer is the speed in which you can transfer them - in as little as 15 to 20 seconds per transfer!

Once you get the hang of it, there will be no stopping you. Start applying DTF transfers quickly and effortlessly today!